Tired of poor quality and delivery issues from its supplier of pressure sensors, a leading technology company for the agricultural sector switched to WIKA for dependable instrumentation and reliable service.

Quality, reliability, customization, and impeccable customer service are key attributes of a trusted parts supplier. Manufacturing companies cannot afford to partner with inflexible and inattentive vendors who deliver poorly made products and suffer from supply-chain issues.

Case in point: A parts supplier made pressure sensors for a leading agricultural technology company, which, among other things, produces direct injection systems for mobile machines. A direct injection system is used in agricultural sprayers to deliver the desired amount of pesticide, fertilizer, or other chemicals to the in-line mixer, where it is combined with water – the carrier fluid – before reaching the sprayer boom. If the chemical-to-water ratio is too low, the solution will not achieve its intended purpose. If the ratio is too high, the solution could burn or otherwise ruin a whole crop. Therefore, it is vital to have an injection system that can accurately control the amount of chemical introduced to the in-line mixer.

The pressure sensor – an integral component of the direct injection system – measures the pressure in a chemical injection pump. This pressure is correlated to the amount of chemicals added to the carrier fluid.

However, the latest technology is of little use if the parts supplier does not meet requested specifications, provides poor-quality products, or misses delivery deadlines. The agricultural technology company was frustrated with its supplier of pressure sensors over issues related to quality and timeliness. The company’s engineers contacted the parts supplier several times, but the latter failed to resolve the problems.

Problem #1: Quality and customization. One of the agricultural technology company’s clients – a leading agricultural machinery manufacturer – required that the pressure sensor in its sprayers’ direct injection systems include a custom O-ring and a grease package in order to avoid potential leaks in the hydraulic system and to ensure accurate measurements. However, the pressure sensor manufacturer often neglected to add these features, leading the client to reject a high number of the company’s products. The client was not happy, and the ag tech company was at risk of losing an important customer’s business.

Problem #2: Reliability and timeliness. The pressure sensor supplier did not plan or schedule production properly. The ag tech company needs a steady stock of units to keep its own production on schedule, but the supplier did not account for the long Chinese New Year holiday and was unable to deliver any pressure sensors for about three weeks during January and February 2017. The ag tech company did not know when the supplier would deliver more sensors and was on the verge of a production shutdown.

The Solution

The agriculture technology company was tired of dealing with a supplier that did not provide on-time delivery of the quality products it requires, so it turned to WIKA. With a culture of partnering with clients and responding promptly to their specifications, WIKA quickly provided the company with what it needed.

WIKA was able to produce a customized version of its MH-2 pressure sensor that met the requirements of the agriculture technology company and its client. No more rejects because of missing or wrong features. Taking advantage of careful planning and the ability to quickly adjust to changing demands, WIKA ramped up production. Within a week, WIKA shipped 1,000 pressure sensors to the company, which then had enough units to continue production. No more uncertainty about supply chain or risk of a costly shutdown.

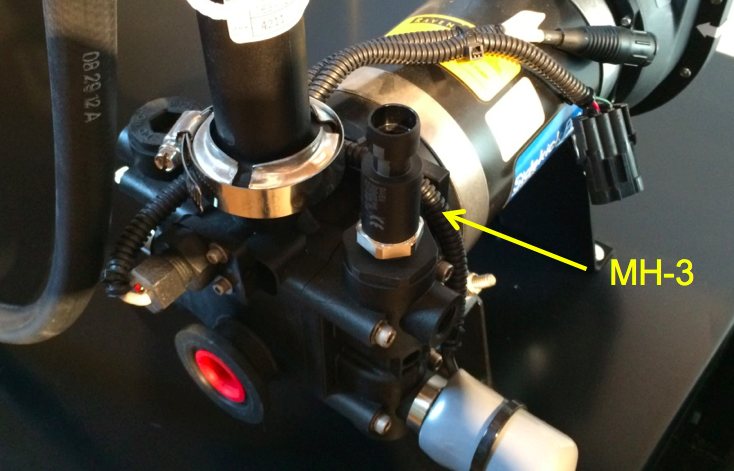

The agriculture technology company was so pleased with the MH-2’s quality and WIKA’s customer service that it is already planning to use WIKA’s MH-3 pressure sensor. The company found that some of MH-3’s features, such as its improved signal-to-noise ratio and diagnostics capabilities, would be assets in the next generation of its electronic control units (ECUs).

In addition, WIKA provides the company with pressure gauges and temperature transmitters for other applications, and is working on a new pressure switch for the injection system.

The MH-3 is a durable, robust, top-of-the-line, and versatile OEM pressure sensor that works well in applications for agricultural mobile machines, including:

- Electronically controlled hydraulics

- Electro-hydraulic travel drive controls

- Electronically controlled continuously variable transmission systems

- Suspension and chassis control units

- Power steering and brake systems

WIKA Stands for Quality and Service

WIKA can customize the MH-3 pressure sensor, as well as numerous other products, to meet the needs of specific applications. WIKA delivers each product on time and exactly as requested by the client. Quality and service have always been the key to WIKA’s successful partnerships around the world.

For more information about any of WIKA’s products, contact our support experts.

Click here to learn more about WIKA product applications in mobile working machines.